Air Mixer

$0.00

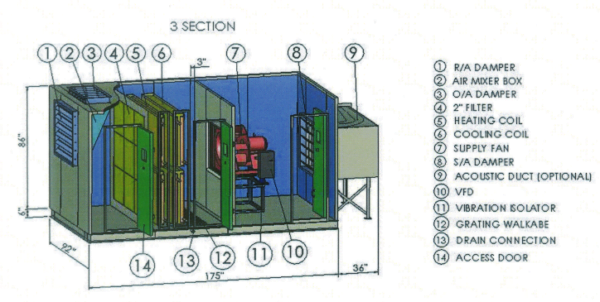

Air Mixer provides a full solution to reducing air stratification in the plenum and coil freeze-ups. The design was conceptualized by looking at the existing problems and devising solutions that best fit the market requirement at an affordable cost. Various programs were used and were studied to see what design and size worked the best.

BENEFITS OF AHU MIXER

Few principles were considered,

- Layer by layer meshing of two gradients of air across the full plenum.

- Effectively churning the air within the Plenum/ box itself without requiring additional space

- Optimizing the flow field with a high ratio of mixing per unit of air.

- Energy savings

PROBLEMS OF AIR STRATIFICATION/FREEZE-UPS/FAILURES

In the HVAC Air Handling system, air stratification resulted from the improper design inherent in moving air streams by keeping air streams of different air temperatures from mixing effectively for a long distance. As a result, it was exceedingly difficult to effectively operate an Air handler as well maintaining the Indoor air quality.

In the winter because of no mixing, coils often got frozen, which damaged the coil as well causing freeze stat trips and sensing errors. In summer, both streams of air were not mixed properly causing additional load on the heat transfer coils leading to large energy bills. Over time the air mixing problem became a serious matter as Outdoor air percentage started increasing as a result of the mandate IAQ requirement. Read More

DESCRIPTION

INDUSTRIAL AIR MIXER – WHY AIR MIXING IS IMPORTANT?

As we are seeing more and more problems occurring at Industrial sites, especially with process facilities where improper mixing of two gradients air is causing failure of process optimization. More site equipment is failing to keep up to perform as one often sees such poor air dilution to an output of burners as well insufficient heat transfer across coils.

AIR STRATIFICATION AND ITS PITFALL

In the HVAC Air Handling system, air stratification resulted from the improper design inherent in moving air streams by keeping air streams of different air temperatures from mixing effectively for a long distance.

As a result, it was difficult to effectively operate an Air handler as well maintaining the Indoor air quality. In the winter as a result of no mixing, coils often got frozen, which damaged the coil as well causing freeze stat trips and sensing errors.

During summer, both streams of air were not combined correctly, causing additional load on the heat transfer coils leading to large energy bills. Over time the air mixing problem became a serious matter as Outdoor air percentage started increasing as a result of mandated IAQ requirements.

CURRENT PROBLEMS VS. EFFECTIVE ECONOMICAL SOLUTION

We have seen many solutions adopted in the market to resolve the problem of air stratification and non-mixing of two-temperature air that were brought into a given space. Earlier glycol additives were used to prevent frozen coils, dampers, high-velocity jets, baffles and specially designed apparatus were conceived to help in mixing. In each case use of a technique slacked the capacity of the air handler like lower capacity, higher pressure drops and an increase of motor horsepower.

Some custom-designed mixers were offered in the past to improve mixing criteria however it was found that air was forced to pass under high velocity through a narrow chamber. These mixers required more downstream space, non-uniform velocity profile and high-pressure drop. Also, it is seen that non-uniform velocity caused additional pressure drop at the downstream components like coils, filters etc.

The mixing device is one of the most effective means of stirring air as well as uniformly mixing two gradients of air temperature homogeneously without causing abrupt temperature blocks in certain areas at the entry to the coil. The downstream area of the mixing device is shorter than standard mixing devices in the industry given only 2-3ft of distance is required to optimize mixing without causing stratification.

Air Mixer provides a full solution to reducing air stratification in the plenum and coil freeze-ups. The design was conceptualized by looking at existing problems and devising solutions that best fit the market requirement at an affordable cost. Various programs were used and were studied to see what design and size worked the best. Few principles were considered,

Few principles were considered,

- Layer by layer meshing of two gradients of air across the full plenum.

- Effectively churning the air within the Plenum/ box itself without requiring additional space.

- Optimizing the flow field with a high ratio of mixing per unit of air.

- Energy savings.

Should you have any requirements, kindly contact us at the factory.

In the present case, the new compact design allowed to bring air from the side of the plenum effectively at the same time able to mix warm and cold air effectively inside the whole cross-section of the mixer with minimum fallout of temperature and mixing.

The air mixing takes helps with thermal dispersion across the thin sheet metal wall inside the mixer along with aerodynamic braiding bars to accentuate mixing within a short distance. This combined with effective air mixing and low-pressure drop makes the unit suitable for most Air Handling Unit AHU manufacturers.

The Air mixing device is one of the most effective means of stirring air as well as uniformly mixing two gradients of air temperature homogeneously without causing abrupt temperature blocks in certain areas at the entry to the coil. The downstream area of the mixing device is shorter than standard mixing devices in the industry given only 2-3ft of distance is required to optimize mixing without causing stratification.

The Mixing device uses alternating layers of Cold (O/A) and Warm (R/A) passageways. The R/A is then directed towards the O/A using diverters located on alternate R/A passageways. If the O/A and R/A dampers are located on the sidewalls of the mixing plenum, the design must ensure that the bottommost passageway is dedicated to the R/A so that cold O/A does not stratify the bottom and thereafter free the coils.

Alternately, if the O/A is on the sidewall and R/A is on the top (or vice versa) then it must be checked that there are no outer passageways on the edges of the mixer where the O/A is not mixing air with R/A (Return Air is not deflected toward that particular passageway if so the opening passage to be blocked).

(Alternately EB Air’s innovative VAV Mixer allows air to be churned at a certain speed by braiders allowing complete mixing without any block of unmixed air. Variable Air Volume VAV Mixer is designed and suited for heavy mixing with a control mechanism that adjusts to changing conditions)

The noise of the mixing device should be checked for low attenuation requirements. Special acoustical media can be embedded in the construction to prevent any unwanted noise from breaking out of the device. For details on design and others, please contact the factory.

VIDEO

APPLICATIONS

- Existing Air Handling Unit having problem with mixing two types of air

- New Air Handling Unit

- Any Area/ Enclosure bringing two types of air and requiring mixing

- Dealing with two extreme temperatures

- Preventing expensive extensions and other appendages inside unit

BENEFITS

- Energy savings by reducing waste heat vis-à-vis lowering operating cost

- Long Life of coils from getting damaged or rusted

- Improved coil efficiency

- Lower equipment down time

- Improves indoor comfort